Sepor Pilot Plants

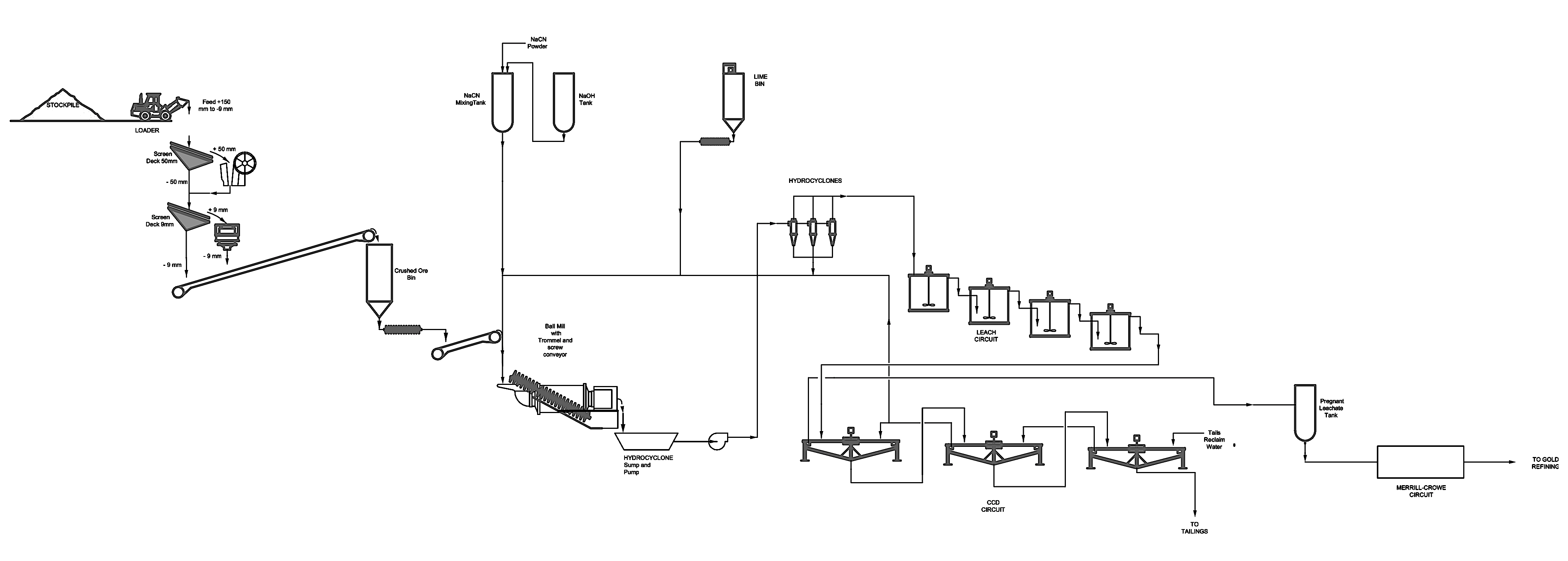

Sepor pilot plants are designed for use in demonstration or confirm design and metallurgical flowsheets. Pilot plants can provide a variety of production scales to be used in new projects as scalable viability and proof of concept. These types of plants can also produce samples of the final product for downstream process design work that can be expected when in full production. Pilot plants can also be used effectively to test new instrumentation and control units within the plant. This reduces monetary and technical risk. The integrated design all allows the unit operations to provide continuous feed or product. Sepor pilot plants scales typically range from <100 kg/hr. to 10 tons/hr. and include Sepor manufactured components.

Generating vital process and metallurgical data that can assist with the design of the full scale mine, this again reduces capital risk but also design time. Should you have a new technology or process pilot plant are well suited to confirm new equipment, and troubleshoot problems.

Bench or batch test work has limitations that lead to a limit in the data used in process design that includes the following factors:

- Particle size distribution

- Influence of process and reaction time

- Effect of process machinery

- Implications of recirculating material streams that carry ore or other materials.

Sepor Pilot plants will provide a substantial impact on your project and provide for proper planning. Sepor as your partner will provide the design, analytical and necessary support with its experienced staff of professionals which is required for an effective pilot plant. Sepor can design a plant to your desired specifications to suit most operations. Such as;

- Heap leach gold column test plants

- Merrill Crowe Plants

- Carbon (CIP) plants

- Gold, Silver and base metals circuits and mineral processing

- Extraction processing plants